Cummins fault codes are critical diagnostic tools for identifying engine issues, ensuring proper maintenance and repairs. A Cummins fault code list PDF provides detailed information on error codes, helping technicians diagnose problems like engine performance issues or emission faults. These codes, such as Error Code 111 for ECM internal failure, are essential for maintaining optimal engine operation and preventing costly downtime. The PDF guide is a valuable resource for understanding and resolving Cummins engine faults efficiently.

Overview of Cummins Engine Fault Codes

Cummins engine fault codes are standardized diagnostic tools designed to identify and communicate issues within the engine system. These codes are part of a comprehensive diagnostic framework, covering various Cummins engine models such as ISB, QSB, and ISX. Each fault code corresponds to a specific problem, ranging from sensor malfunctions to fuel system issues. For example, Error Code 111 indicates an ECM internal failure, while other codes may relate to turbocharger performance or emission control systems. The codes are structured using SPN (Suspect Parameter Number) and FMI (Failure Mode Indicator) to provide detailed insights for technicians. Official Cummins resources, such as PDF guides, offer extensive lists and explanations, ensuring accurate troubleshooting and repairs. These codes are essential for maintaining engine health and performance.

Importance of Understanding Fault Codes for Maintenance

Understanding Cummins fault codes is crucial for effective maintenance and extending engine lifespan. Fault codes provide clear insights into engine issues, enabling timely repairs and minimizing downtime. By referencing a Cummins fault code list PDF, technicians can identify problems like ECM failures or sensor malfunctions, ensuring precise diagnostics. Regular monitoring of these codes helps prevent minor issues from escalating into major repairs. Additionally, fault codes guide maintenance schedules, optimizing engine performance and reducing operational costs. Proper interpretation of codes ensures compliance with emissions standards and enhances overall engine reliability, making them an indispensable tool for maintaining Cummins engines efficiently and safely.

How to Read Cummins Fault Codes

Reading Cummins fault codes involves using diagnostic tools or the J1939 protocol to retrieve codes from the ECM. Referencing a Cummins fault code list PDF helps interpret codes like SPN and FMI, ensuring accurate diagnostics and repairs.

Understanding the Structure of Fault Codes

Cummins fault codes are structured to provide clear diagnostic information. Each code consists of an SPN (Suspect Parameter Number), FMI (Failure Mode Indicator), and Lamp status. The SPN identifies the specific parameter with the issue, while the FMI describes the type of failure, such as “low voltage” or “high pressure.” The Lamp indicates whether the fault is active or stored. For example, SPN 16 with FMI 00 might relate to a fuel system issue. Referencing a Cummins fault code list PDF helps decode these numbers, ensuring accurate troubleshooting and repairs. Understanding this structure is essential for diagnosing and resolving engine problems effectively.

Using Diagnostic Tools for Fault Code Retrieval

Diagnosing Cummins engine issues requires the use of specialized tools to retrieve fault codes. Tools like fault code scanners, diagnostic software, and the Cummins PowerSpec tool allow technicians to access and interpret error codes stored in the ECM. These tools connect to the engine’s J1939 CAN network, displaying active or stored faults. For example, the Cummins PowerSpec tool provides detailed code information, including SPN, FMI, and lamp status. By using these tools, technicians can quickly identify issues, such as Error Code 111 for ECM internal failure, and perform necessary repairs. Regular use of diagnostic tools ensures efficient troubleshooting and minimizes downtime for Cummins engines.

Cummins Engine Fault Codes by Model

Cummins engines vary by model, each with specific fault codes. The Cummins fault code list PDF organizes codes for models like ISB, QSB, ISX, and QSX, ensuring precise diagnostics and repairs.

Cummins ISB Fault Codes

Cummins ISB fault codes are specific to the ISB engine model, providing detailed insights into engine performance issues. These codes, such as Error Code 111 for ECM internal failure, are structured using SPN (Suspect Parameter Number) and FMI (Fault Mode Indicator) to identify malfunctions accurately. The Cummins fault code list PDF includes codes for various ISB engine issues, ranging from fuel system problems to sensor malfunctions. Each code is accompanied by descriptions and troubleshooting steps, ensuring technicians can diagnose and repair issues efficiently. Regularly updated PDF guides are essential for accessing the latest information on ISB fault codes, ensuring maintenance and repairs align with current standards.

Cummins QSB Fault Codes

Cummins QSB fault codes are designed to help diagnose and repair issues specific to QSB engines. These codes, detailed in the Cummins fault code list PDF, cover a wide range of potential problems, from fuel system malfunctions to emission-related faults. Each code is paired with a description, such as Error Code 111 for ECM internal failure, providing clear guidance for technicians. The PDF guide offers a comprehensive list of QSB-specific fault codes, ensuring accurate troubleshooting and efficient repairs. By referencing these codes, professionals can maintain optimal engine performance and comply with emissions standards, making the PDF an indispensable resource for QSB engine maintenance and diagnostics.

Cummins ISX Fault Codes

Cummins ISX fault codes are essential for diagnosing and resolving issues in ISX engines. The Cummins fault code list PDF provides detailed information on these codes, such as Error Code 111, which indicates an ECM internal failure. These codes help identify problems like fuel system malfunctions, emission control issues, or sensor failures. By referencing the PDF guide, technicians can quickly understand the cause of a fault and perform necessary repairs. The ISX-specific codes ensure accurate diagnostics, preventing potential engine damage and downtime. This resource is vital for maintaining the performance and reliability of Cummins ISX engines in various applications, from trucks to industrial equipment.

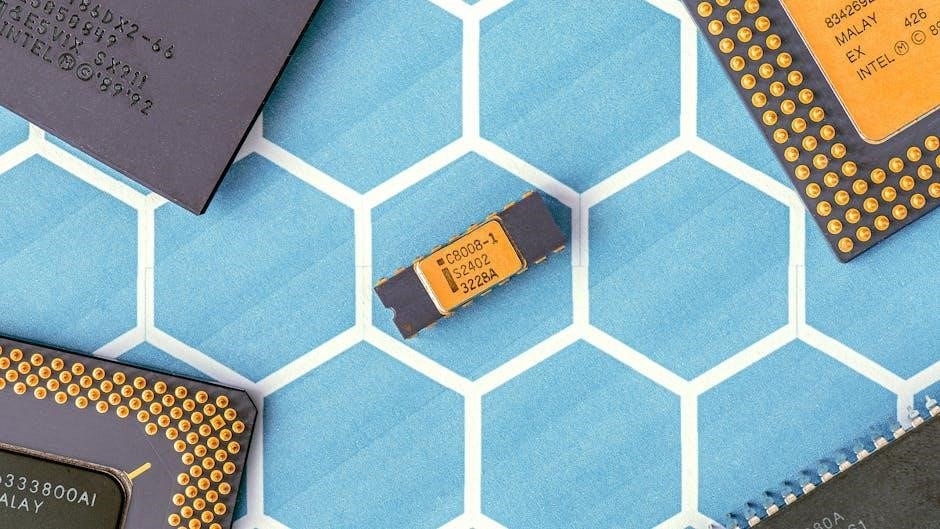

SPN and FMI Codes in Cummins Engines

SPN and FMI codes are critical for diagnosing Cummins engine faults. The Cummins fault code list PDF details these codes, enabling precise identification of issues like sensor failures or system malfunctions. By combining SPN (Suspect Parameter Number) and FMI (Failure Mode Identifier), technicians can pinpoint the root cause of errors, ensuring efficient repairs. This structured approach simplifies troubleshooting, making it essential for maintaining engine performance and reliability. The PDF guide provides a comprehensive reference for interpreting these codes accurately.

SAE J1939 Protocol and Its Role in Fault Codes

The SAE J1939 protocol is a standardized communication network used in heavy-duty vehicles, including Cummins engines, to transmit diagnostic data. It enables electronic control units (ECUs) to share information, such as fault codes, across the vehicle; In Cummins engines, the J1939 protocol plays a key role in identifying and reporting issues through SPN (Suspect Parameter Number) and FMI (Failure Mode Identifier) codes. This protocol ensures that fault codes are structured and standardized, making it easier for technicians to diagnose problems. The Cummins fault code list PDF provides detailed mappings of these codes, linking SPNs to specific faults and FMIs to failure modes. This standardized approach enhances diagnostic accuracy and efficiency, allowing for quicker repairs and reduced downtime. By leveraging the J1939 protocol, Cummins engines ensure seamless communication between components, simplifying the troubleshooting process.

Interpreting FMI Codes for Accurate Diagnostics

FMI (Failure Mode Identifier) codes are essential for pinpointing the root cause of faults in Cummins engines. These codes, often used alongside SPNs, describe the specific type of failure. For instance, an FMI code of “11” might indicate a “circuit open” issue, while “12” could signify a “circuit short to ground.” The Cummins fault code list PDF provides detailed explanations of each FMI code, enabling technicians to understand the nature of the malfunction. By interpreting FMI codes accurately, technicians can identify whether the problem lies in a sensor, wiring, or another component. This precise information ensures targeted repairs, reducing diagnostic time and improving overall efficiency. Accurate FMI interpretation is crucial for maintaining engine performance and preventing further damage.

Troubleshooting Common Cummins Fault Codes

Troubleshooting Cummins fault codes involves identifying the root cause of issues like error code 111 (ECM internal failure) by checking wiring, sensors, and system performance. A Cummins fault code list PDF provides step-by-step guidance for diagnosing and resolving common faults, ensuring efficient repairs and minimizing downtime. Regular checks and updates help prevent recurring issues, keeping engines running smoothly.

Step-by-Step Diagnostic Process

Diagnosing Cummins engine faults requires a systematic approach. Start by identifying the fault code using diagnostic tools like FIS or FCAR F3. Consult the Cummins fault code list PDF to understand the code, such as Error Code 111 for ECM failure. Next, inspect related components like sensors, wiring, and connectors for damage or malfunctions. Use the PDF guide to trace the circuit and perform tests. If necessary, update or replace faulty parts. Finally, clear the fault code and test the system to ensure the issue is resolved. This structured process ensures accurate and efficient troubleshooting, minimizing downtime and ensuring reliable engine performance. Regular updates to the fault code list are essential for staying current with diagnostics.

Case Study: Resolving ECM Internal Failure (Error Code 111)

Error Code 111 indicates an ECM internal failure in Cummins engines, affecting models like ISB, QSB, and ISX. To resolve this, first, ensure the ECM software is up-to-date. Check for any loose or corroded connections in the ECM wiring harness. If damage is found, replace the ECM and clear the fault code using diagnostic tools like FIS or FCAR F3. Always refer to the Cummins fault code list PDF for specific instructions. After repairs, test the engine to confirm the issue is resolved. This structured approach ensures the ECM operates correctly, restoring engine performance and reliability. Consult the latest service manual for updated procedures.

Resources for Cummins Fault Code Lookup

Official Cummins documentation and PDF manuals provide comprehensive fault code lists. Online databases and service manuals offer detailed troubleshooting steps for common issues, ensuring accurate diagnostics and repairs.

Official Cummins Documentation and Manuals

Official Cummins documentation and manuals are indispensable for accurate fault code interpretation. These resources provide detailed lists of codes, such as Error Code 111 for ECM internal failure, along with repair procedures. They include troubleshooting guides for specific engine models like ISB, QSB, and ISX. Manuals are available in PDF format, covering diagnostics for systems like the CAPS fuel system. Cummins service portals and certified dealers offer access to these documents, ensuring technicians have the latest information. Referencing official manuals is crucial for maintaining compliance with manufacturer recommendations and ensuring reliable engine performance.

Online Databases and PDF Guides for Fault Codes

Online databases and PDF guides offer comprehensive access to Cummins fault codes, enabling quick diagnosis and repair. These resources list codes like Error Code 111, detailing ECM failures and troubleshooting steps. PDF documents cover various engine models, including ISB, QSB, and ISX, with detailed fault descriptions. Websites like Cummins service portals provide downloadable guides, ensuring technicians have up-to-date information. Additionally, forums and diagnostic tool manuals, such as FIS, offer supplementary data. These resources are essential for efficient fault resolution, aiding professionals in maintaining Cummins engines effectively and minimizing downtime.

Understanding Cummins fault codes is crucial for effective engine maintenance. Utilizing resources like PDF guides ensures accurate diagnostics and timely repairs, enhancing overall engine performance and longevity.

Best Practices for Using Fault Codes in Maintenance

Regularly consulting a Cummins fault code list PDF ensures accurate diagnostics and efficient repairs. Technicians should always verify codes using official Cummins tools and refer to the latest manuals for updated information. Documenting each fault code encounter helps track recurring issues, improving long-term maintenance strategies. Prioritizing critical codes, such as those indicating internal failures, prevents severe engine damage. Training staff on fault code interpretation ensures consistency and reduces diagnostic errors. By integrating fault code data into maintenance schedules, fleets can enhance engine performance, minimize downtime, and lower operational costs. Consistent adherence to these practices optimizes engine health and extends service life.