Genie fault codes are essential diagnostic tools for identifying issues in Genie equipment‚ providing clear indicators for technicians to troubleshoot and resolve malfunctions efficiently․ Referencing the Genie service manual‚ starting on page 182‚ ensures accurate interpretations of codes for models like GS-2046‚ GS-2646‚ and GS-3246‚ helping maintain equipment performance and safety․

Overview of the Importance of Fault Codes in Genie Equipment

Fault codes play a critical role in the diagnostic process for Genie equipment‚ enabling technicians to identify and address malfunctions efficiently․ These codes provide specific insights into system errors‚ helping to pinpoint issues ranging from internal ECM faults to platform overload warnings․ By referencing the Genie service manual‚ particularly sections like page 182‚ technicians can decode these signals‚ ensuring timely repairs and minimizing downtime․ Fault codes are essential for maintaining equipment performance‚ operator safety‚ and overall operational reliability․ They serve as a cornerstone for proactive maintenance‚ allowing users to resolve problems before they escalate‚ thus safeguarding both the machine and its users․

Understanding How Genie Fault Codes Work

Genie fault codes are generated by the equipment’s system to indicate specific malfunctions‚ such as internal ECM errors or platform faults․ These codes‚ like 01 or 20‚ help technicians identify issues efficiently;

The System Behind Code Generation and Diagnosis

The system behind Genie fault code generation involves advanced diagnostic processes within the equipment’s control module․ When a malfunction occurs‚ sensors detect anomalies and relay data to the ECM‚ which generates specific codes․ These codes‚ such as 01 (internal ECM error) or 02 (ECM fault)‚ are stored in the system’s memory․ Technicians retrieve these codes using diagnostic tools or LED readouts‚ enabling precise identification of issues․ The process ensures efficient troubleshooting by linking each code to a detailed description in the service manual‚ guiding repairs and minimizing downtime․ This systematic approach simplifies complex diagnostics‚ ensuring reliability and safety in Genie equipment operation․

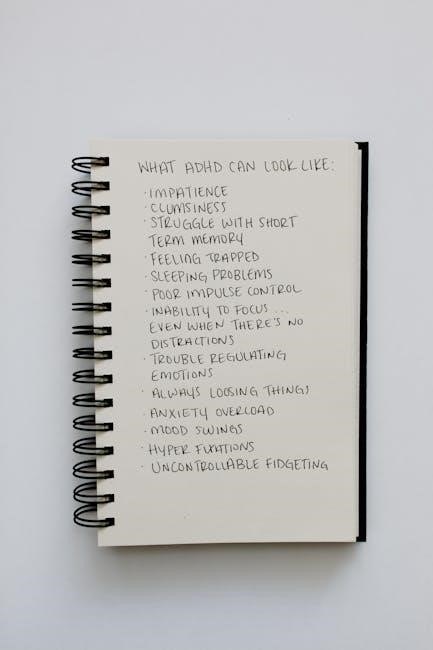

Common Genie Fault Codes

Genie equipment frequently displays codes like 01 (internal ECM error)‚ 02 (ECM fault)‚ and 20 (fault-memory issue)․ These codes indicate system malfunctions‚ guiding technicians in diagnostics and repairs․

Critical vs․ Non-Critical Codes and Their Implications

Genie fault codes are categorized into critical and non-critical‚ each requiring different levels of urgency․ Critical codes‚ such as 01 (internal ECM error) or 02 (ECM fault)‚ indicate severe system malfunctions that demand immediate attention to prevent equipment damage or safety hazards․ Non-critical codes‚ like 20 (fault-memory issue)‚ may not halt operations but should still be addressed to avoid escalating issues․ Understanding this distinction is vital for prioritizing repairs and ensuring operational safety․ Technicians must refer to the Genie service manual for precise interpretations and actions‚ ensuring timely resolution to maintain equipment performance and prevent downtime․

Troubleshooting with LED Readouts

Genie equipment uses LED readouts to display fault codes‚ enabling quick identification of malfunctions․ These diagnostic tools are essential for efficient troubleshooting‚ as outlined in the service manual․

Using Diagnostic LEDs for Effective Problem-Solving

Genie equipment features diagnostic LEDs that display fault codes through specific flash patterns‚ aiding technicians in identifying malfunctions․ By referencing the service manual‚ starting on page 182‚ these LED readouts can be interpreted to pinpoint issues efficiently․ Each code corresponds to a unique problem‚ enabling swift resolution․ The LED system is a critical tool for troubleshooting‚ ensuring that technicians can address errors without delays․ Regular use of these diagnostic LEDs helps maintain equipment performance and extends its operational lifespan․ This approach streamlines maintenance processes‚ reducing downtime and ensuring safety standards are upheld․

Role of Service Manuals in Fault Resolution

Service manuals are vital for interpreting Genie fault codes‚ providing detailed repair information and ensuring accurate diagnosis․ Referencing manuals like the Genie Scissor Service Manual (page 182) is essential for resolving issues efficiently and safely․

How to Utilize Manuals for Code Interpretation

To effectively interpret Genie fault codes‚ service manuals provide detailed guidance․ Start by locating the specific manual for your equipment‚ such as the Genie Scissor Service Manual‚ which begins fault code explanations on page 182․ Identify the fault code displayed on your machine and cross-reference it with the manual’s diagnostic charts․ For models like GS-2046‚ GS-2646‚ and GS-3246‚ these manuals outline the meaning of each code and suggest repair procedures․ Use the manual’s troubleshooting sections to pinpoint issues and apply the recommended fixes․ This systematic approach ensures accurate diagnosis and efficient resolution of faults‚ minimizing downtime and ensuring safety․

Specific Genie Models and Their Fault Codes

Genie models like GS-2046‚ GS-2646‚ and GS-3246 have unique fault codes documented in their service manuals․ These codes help technicians identify and address model-specific issues efficiently․

Examining Codes for GS-2046‚ GS-2646‚ and GS-3246 Models

The GS-2046‚ GS-2646‚ and GS-3246 models each have distinct fault codes detailed in their service manuals‚ starting on page 182․ These codes help technicians diagnose issues like sensor malfunctions or motor errors․ By referencing the Genie fault code list PDF‚ users can identify model-specific problems‚ such as platform overload faults or ECM errors․ Regularly consulting these resources ensures timely repairs‚ maintaining equipment safety and productivity․ The manuals also provide troubleshooting steps and preventive measures‚ making them indispensable for technicians working with these Genie models․ Understanding these codes is crucial for efficient and accurate fault resolution․

Diagnostic Tools for Fault Retrieval

Essential tools include multimeters‚ diagnostic software‚ and service manuals․ These aids help retrieve and interpret fault codes‚ enabling technicians to diagnose and repair issues efficiently‚ ensuring productivity․

Necessary Tools and Software for Technicians

Technicians require specialized tools like multimeters and diagnostic software to retrieve and interpret Genie fault codes․ Service manuals‚ such as the Genie Scissor Service and Repair Manual‚ provide detailed code explanations and troubleshooting steps․ These resources‚ available in PDF format‚ list codes for specific models including the GS-2046‚ GS-2646‚ and GS-3246․ Additionally‚ diagnostic LED readouts on the equipment offer visual cues for initial fault identification․ By combining these tools‚ technicians can efficiently diagnose and address malfunctions‚ ensuring equipment operates safely and effectively․ Regular updates to these resources help technicians stay informed about new codes and procedures․

Best Practices in Maintenance

Regular inspections and adherence to scheduled maintenance routines help prevent faults․ Referencing Genie service manuals ensures compliance with guidelines‚ minimizing downtime and extending equipment lifespan effectively․

Preventative Measures to Avoid Common Faults

Preventative maintenance is crucial for minimizing faults in Genie equipment․ Regularly inspecting systems‚ adhering to service schedules‚ and ensuring proper operation can prevent issues․ Using diagnostic LEDs to monitor equipment health helps identify potential problems early․ Referencing the Genie fault code list PDF and service manuals ensures technicians follow proven procedures․ Updating software and firmware regularly is also essential for optimal performance․ By implementing these measures‚ operators can reduce downtime‚ extend equipment lifespan‚ and maintain workplace safety․ Consistent upkeep not only prevents faults but also enhances overall efficiency and reliability of Genie lifts and trucks․

Genie Fault Code List PDF Resources

The Genie fault code list PDF is a valuable resource for technicians‚ providing detailed diagnostic information․ It is available in service manuals or downloadable from the manufacturer’s website‚ ensuring easy access for troubleshooting and repair․

Locating Reliable PDFs for Fault Code References

Reliable Genie fault code list PDFs can be found in official service manuals or through authorized Genie dealers․ These documents‚ such as the Genie Scissor Service and Repair Manual‚ provide detailed fault code descriptions and troubleshooting guides․ Specific models like the GS-2046‚ GS-2646‚ and GS-3246 have dedicated sections in these manuals‚ ensuring accurate diagnosis․ Technicians can access these resources by visiting the Genie website or contacting local dealers via the Genie Dealer Locator tool․ Using genuine PDFs guarantees up-to-date and accurate information‚ which is critical for safe and effective equipment maintenance and repair․

Effective management of Genie fault codes ensures equipment reliability and safety․ Utilizing official PDF resources and service manuals is crucial for accurate diagnostics and maintaining optimal performance․

Summarizing the Importance of Effective Fault Code Management

Effective fault code management is crucial for maintaining Genie equipment performance and safety․ By utilizing resources like the Genie Scissor Service and Repair Manual‚ technicians can quickly diagnose and address issues․ Diagnostic LEDs and tools provide clear insights‚ enabling efficient troubleshooting․ Regular reference to official PDF guides ensures accurate interpretations of codes like Platform Overload System Fault Codes․ This approach minimizes downtime‚ supports safety standards‚ and extends equipment lifespan․ Proper fault code management is essential for maintaining productivity and ensuring reliable operation of Genie lifts and forklifts across various models‚ including GS-2046‚ GS-2646‚ and GS-3246․